In the anodizing process, also called anodization, the building up of a very hard and scratch-resistant aluminium oxide layer in an electrochemical process is facilitated. It protects the aluminium from direct mechanical influences and is resistant to weathering and corrosion.

Aluminium surfaces can optionally be chemically or mechanically pre-treated before anodising. This changes the structure, reflective properties and effect of the surface.

For metal sheets, we offer the pre-treatment options degreasing and deoxidising (E0) and the most common chemical pre-treatment pickling (E6). Profiles can be degreased and deoxidised (E0), ground (E1), brushed (E2), ground and micro-polished (E4) or pickled (E6).

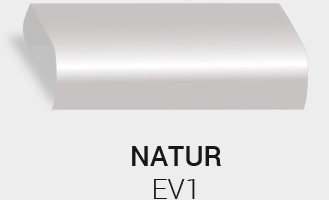

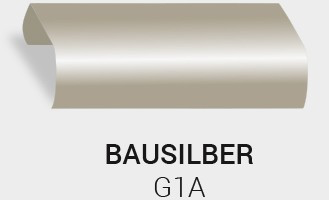

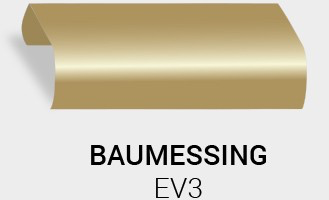

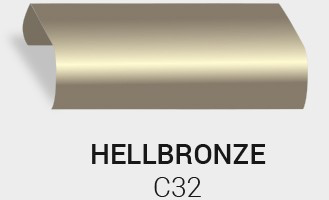

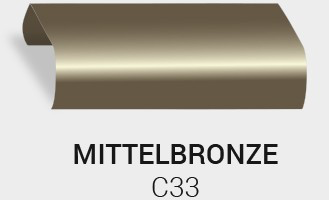

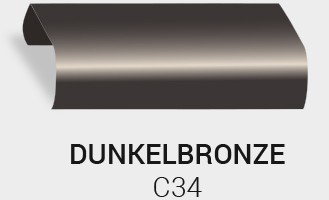

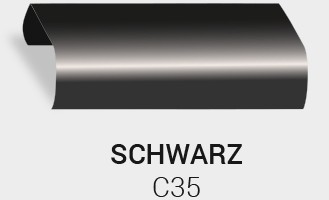

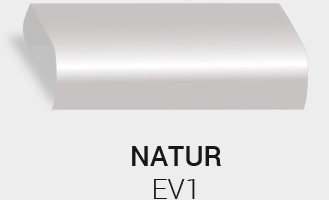

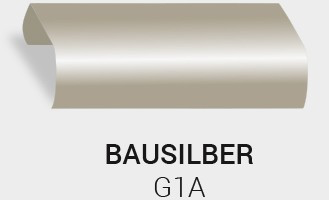

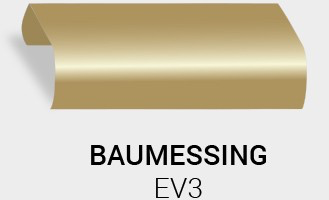

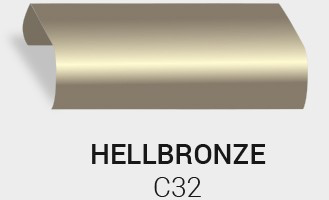

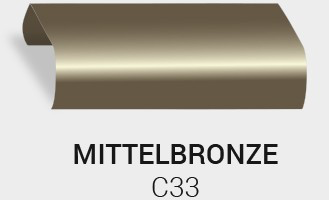

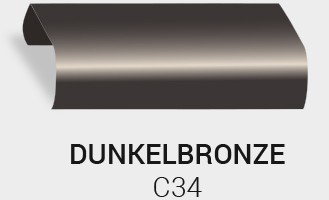

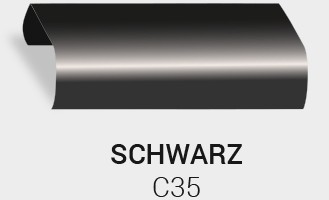

Anodized finishes in silver and bronze tones

The timeless surfaces have been popular with planners and architects for decades. From silver to black, we offer all common colours.

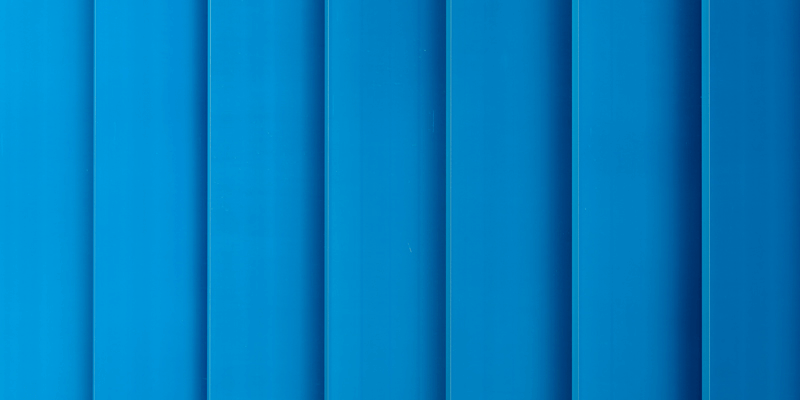

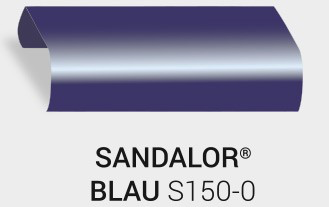

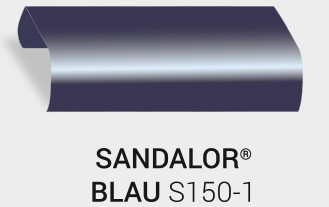

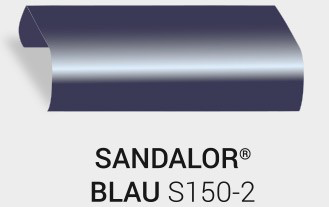

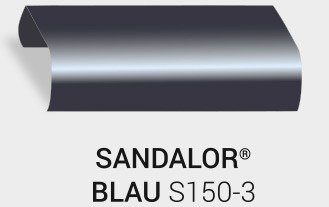

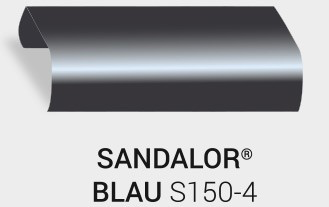

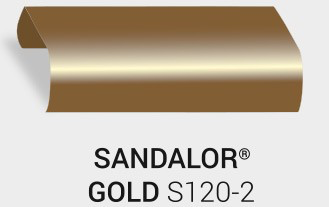

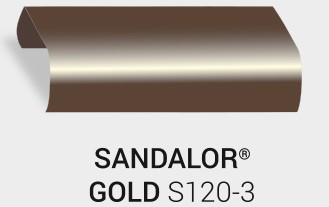

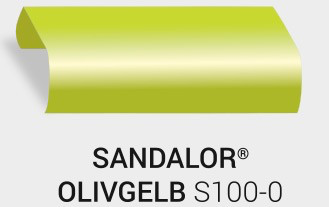

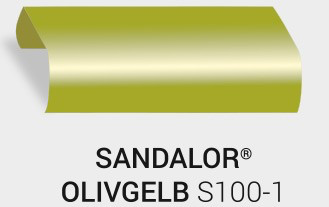

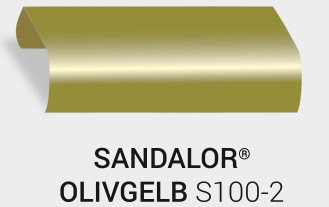

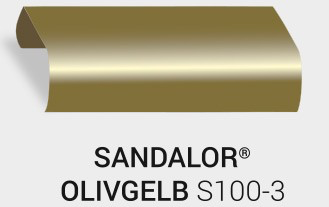

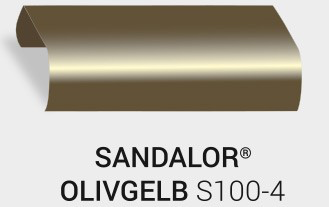

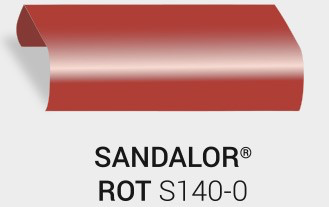

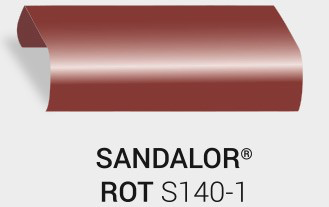

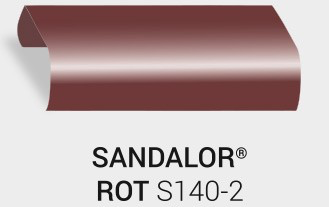

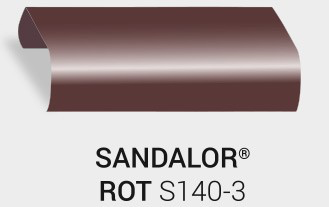

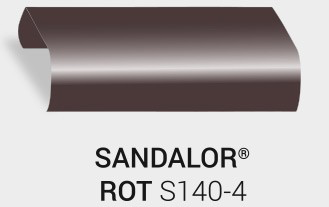

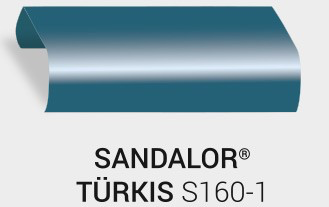

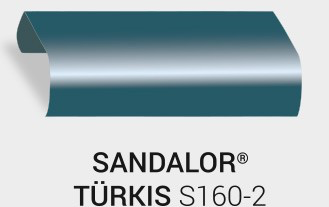

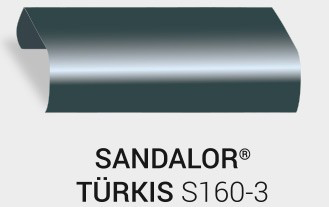

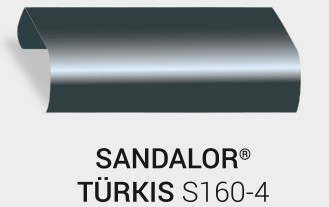

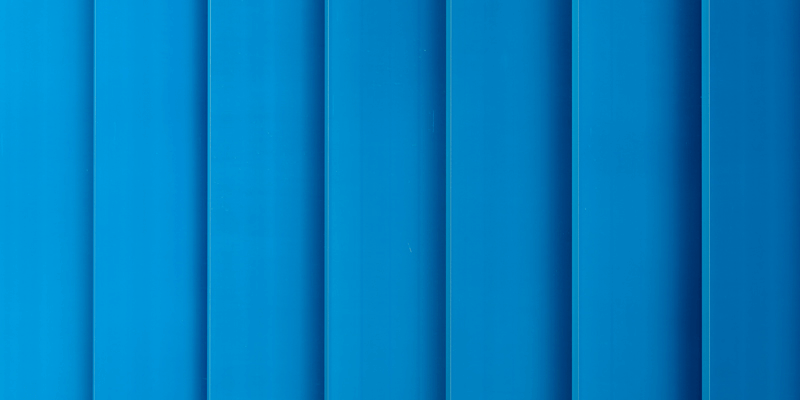

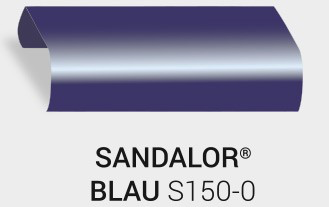

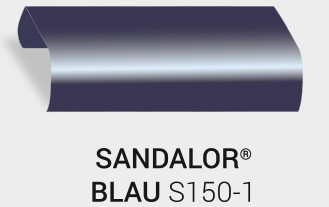

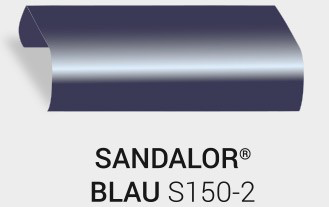

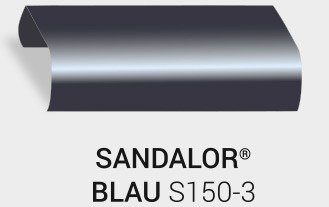

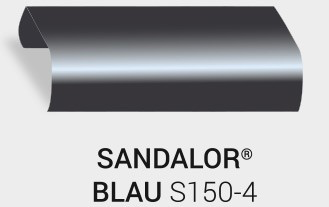

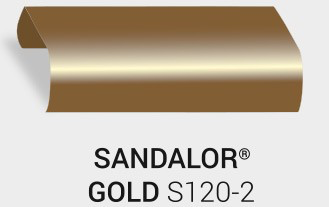

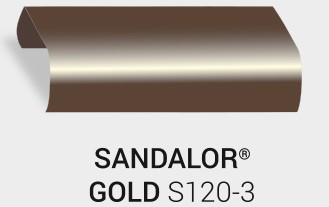

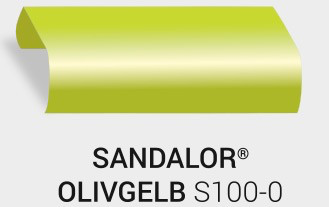

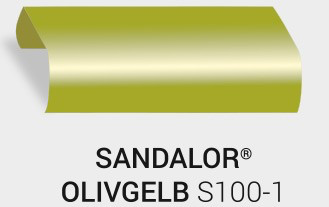

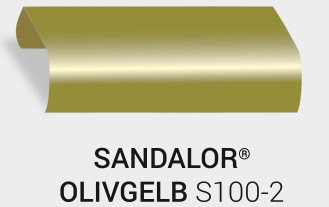

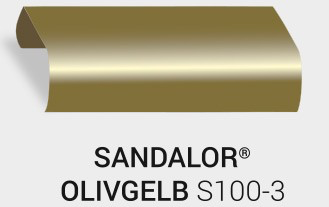

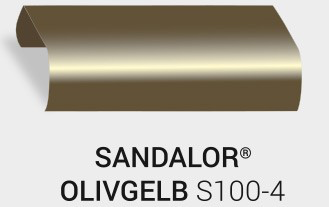

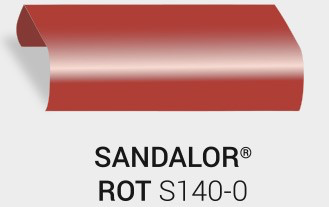

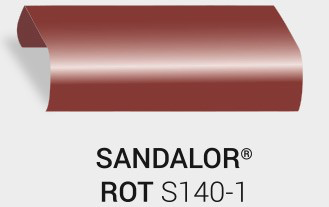

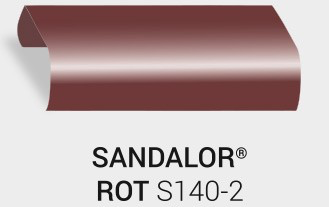

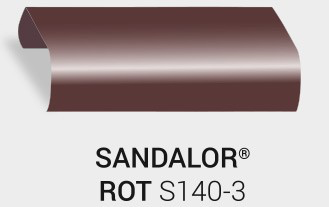

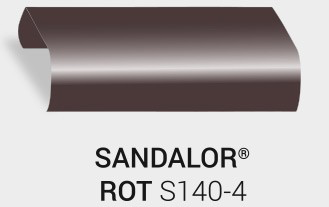

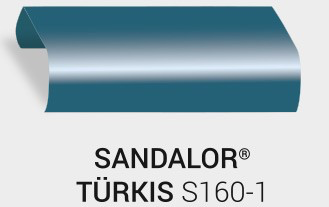

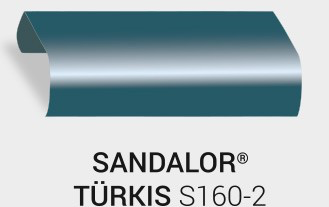

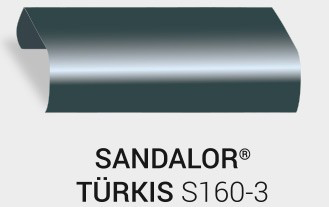

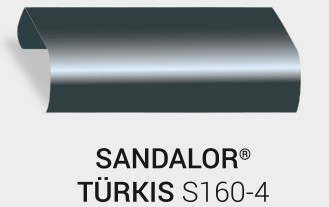

SANDALOR® coloured anodizing

SANDALOR® surfaces are colourful and weather-resistant. Due to their lightfastness, the colourful shades are equally suitable for exterior and interior use.

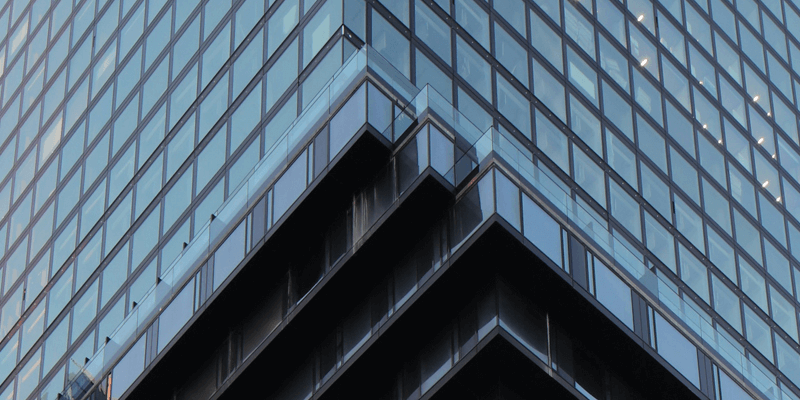

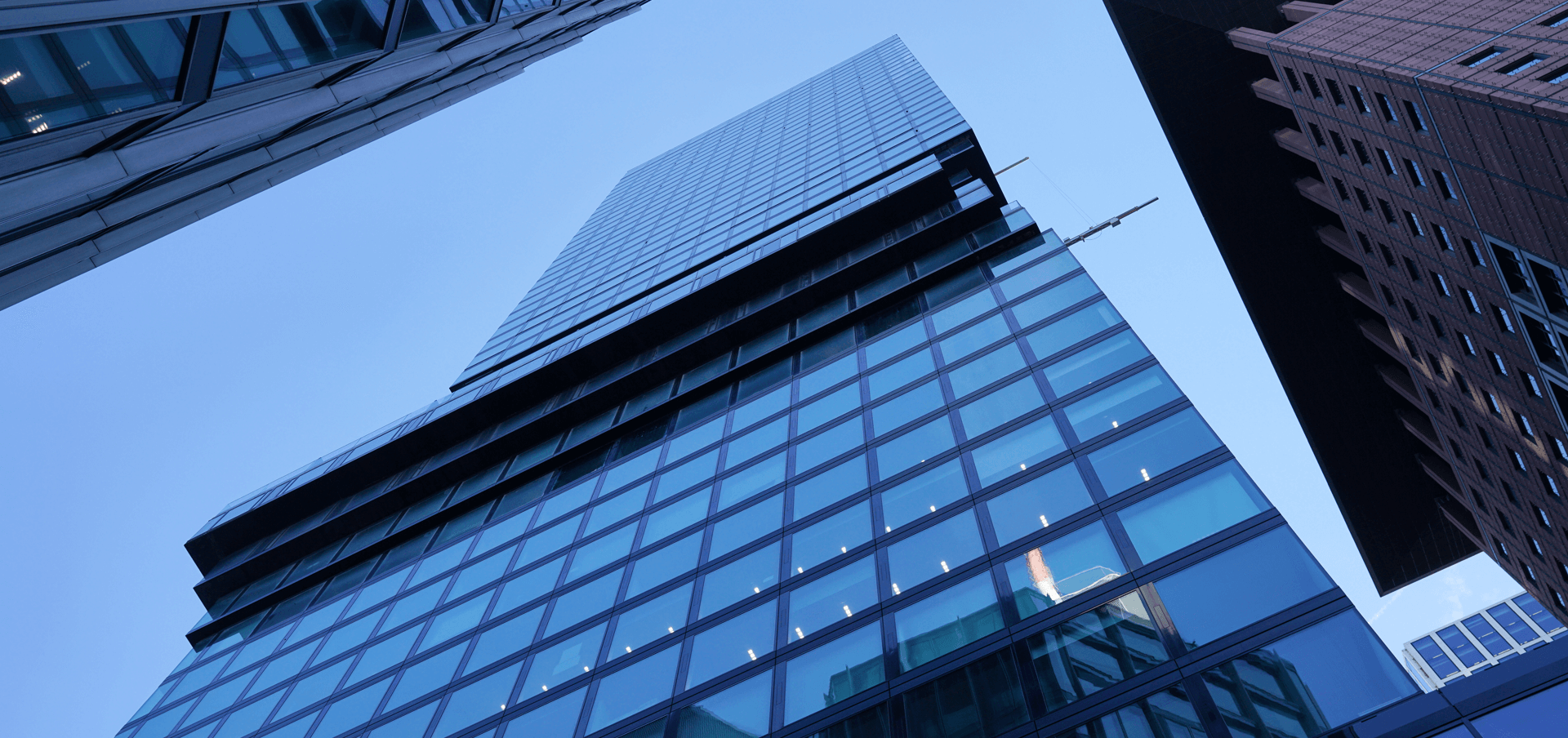

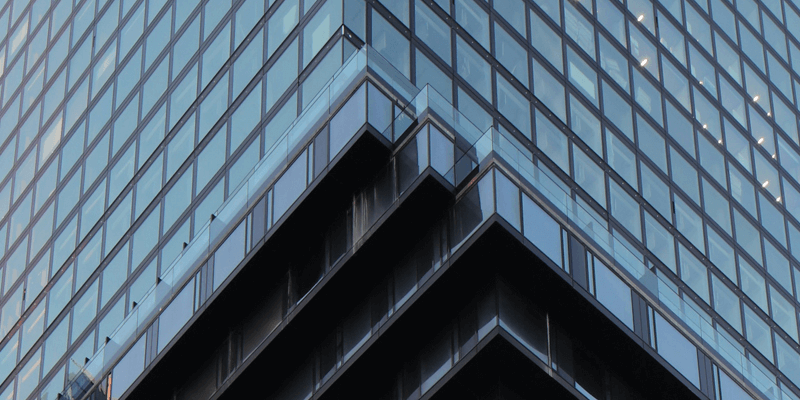

Structural Glazing Anodizing

If required, we anodise in accordance with the guidelines of ETAG 002. The anodized layer then fulfils special requirements, so that for example glass might safely and permanently be attached and bonded.

Anodizing according to British Standard

We also anodize in accordance with British Standard (BS 3987) which is traditionally required for many façades in the UK.

Anodizing always preserves the natural aluminium look – because it is a process that changes the surface of the metal itself and does not cover it. Colour pigments are always embedded in the top layer of the metal.

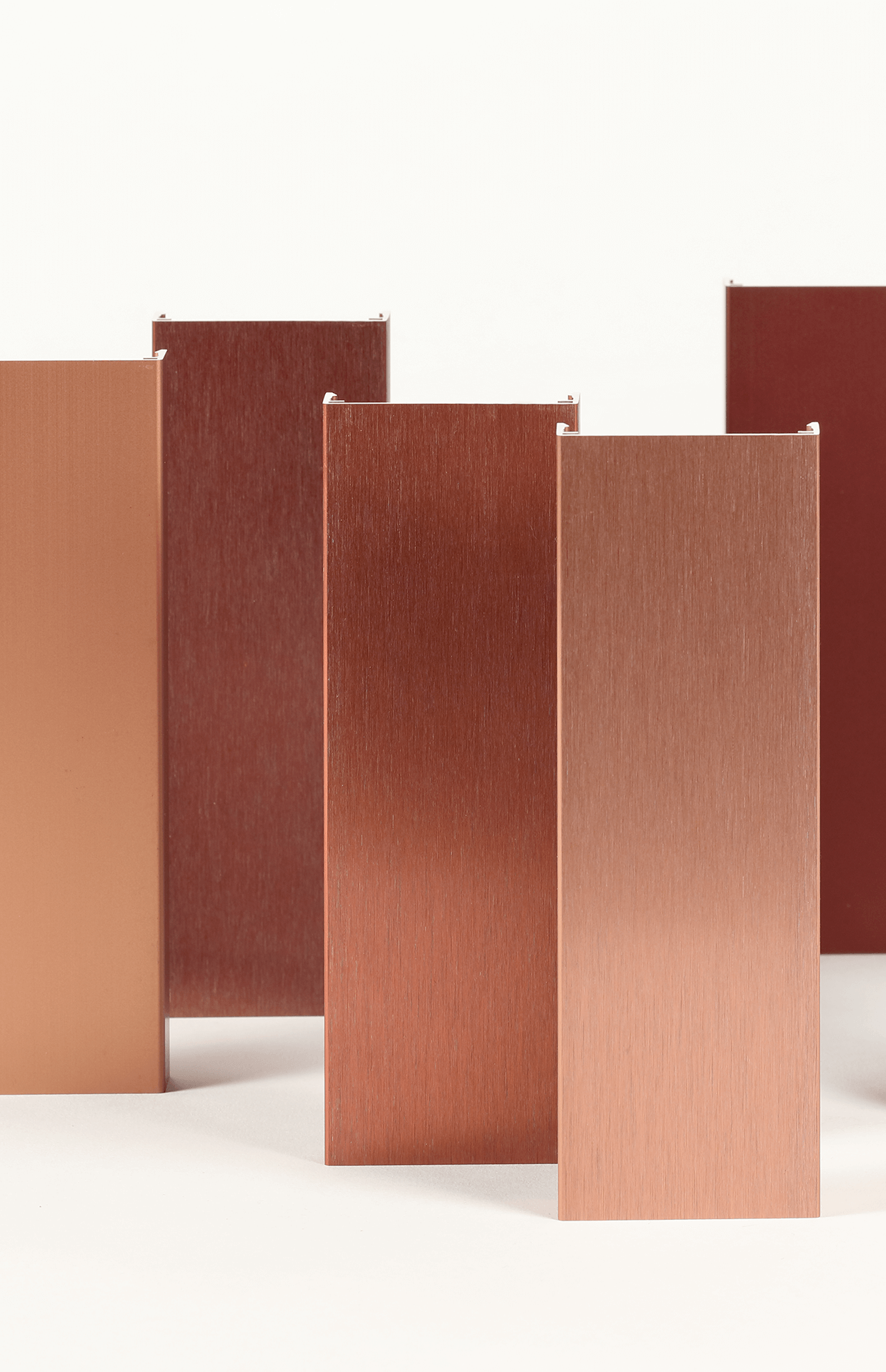

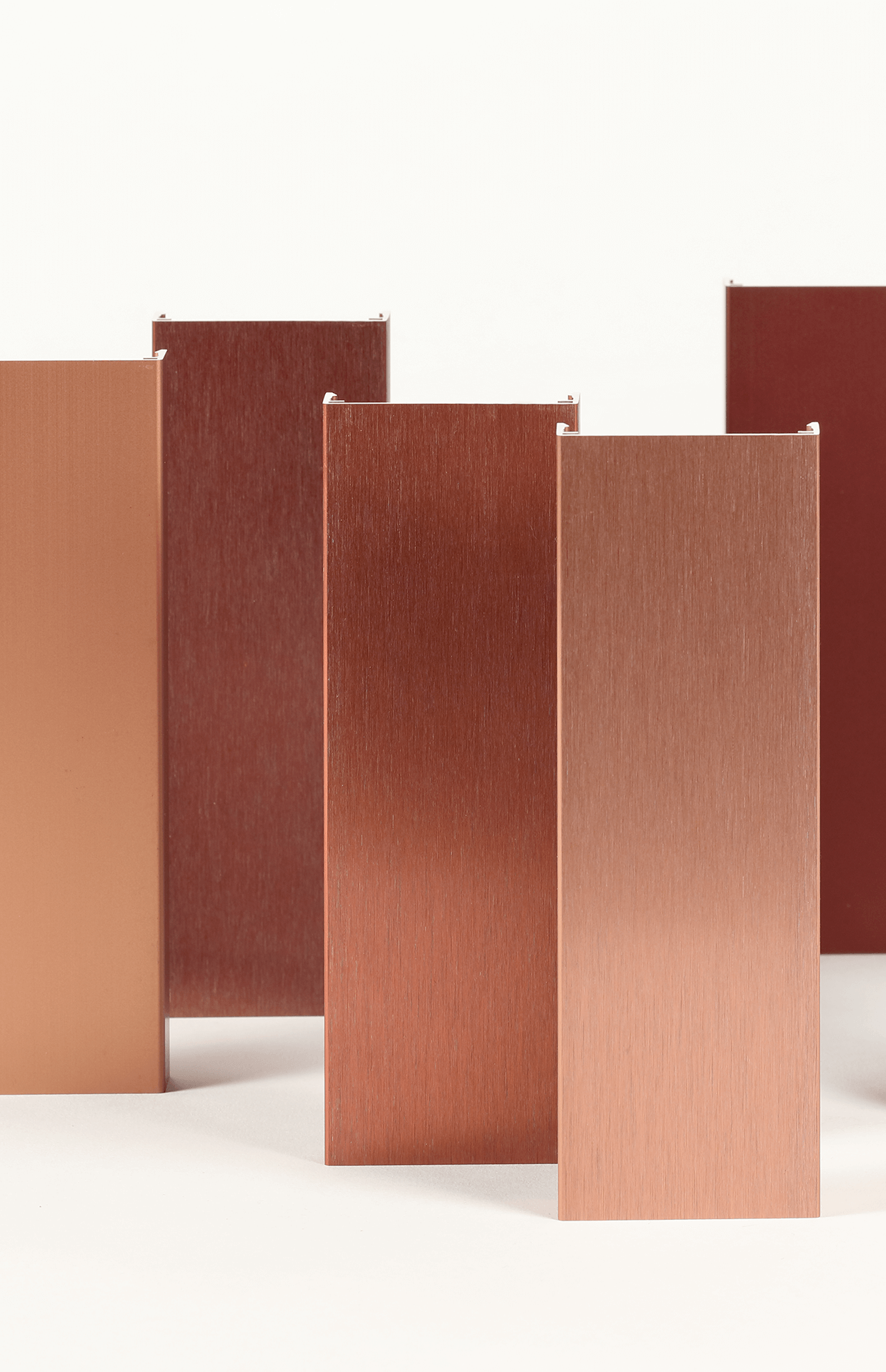

The new copper anodized materials can be used to create shiny copper-orange or matt-shimmering dark red facades. The copper-colored anodized surfaces have major advantages over real copper facades: The weatherproof aluminum facades do not show the oxidation phenomena typical of copper, which result in significant color changes over time. The unsightly traces of copper corrosion cannot be found on anodized surfaces either. Our copper anodizers are available in the Terracopper 1,2,3 and Bordeaux 1,2,3 series. All copper anodized materials are offered in the usual pre-treatment variants.

25 colors can be reproduced using the SANDALOR® process.

The colors suitable for outdoor use are light-resistant and colorful.

A selection from the SANDALOR® design series:

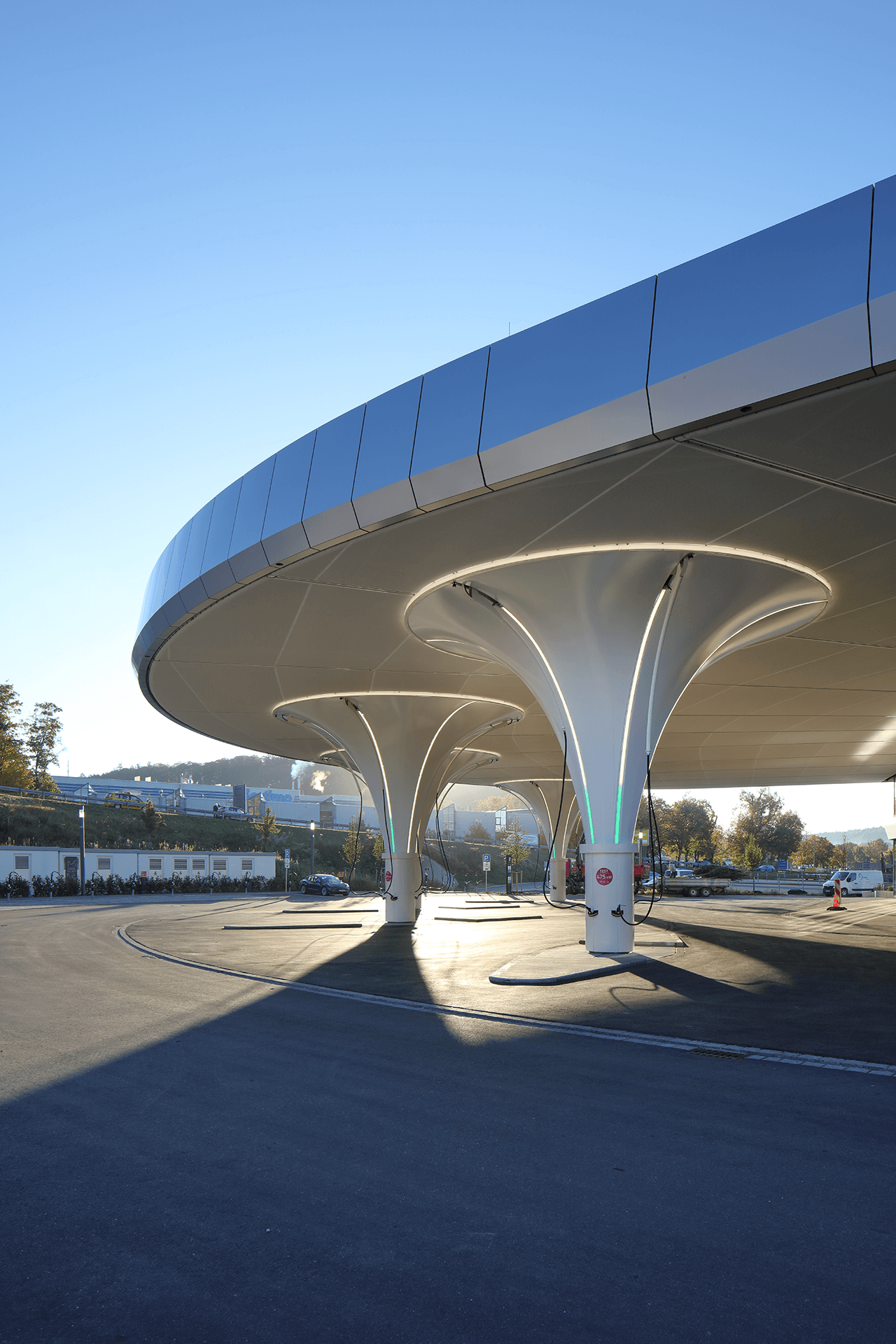

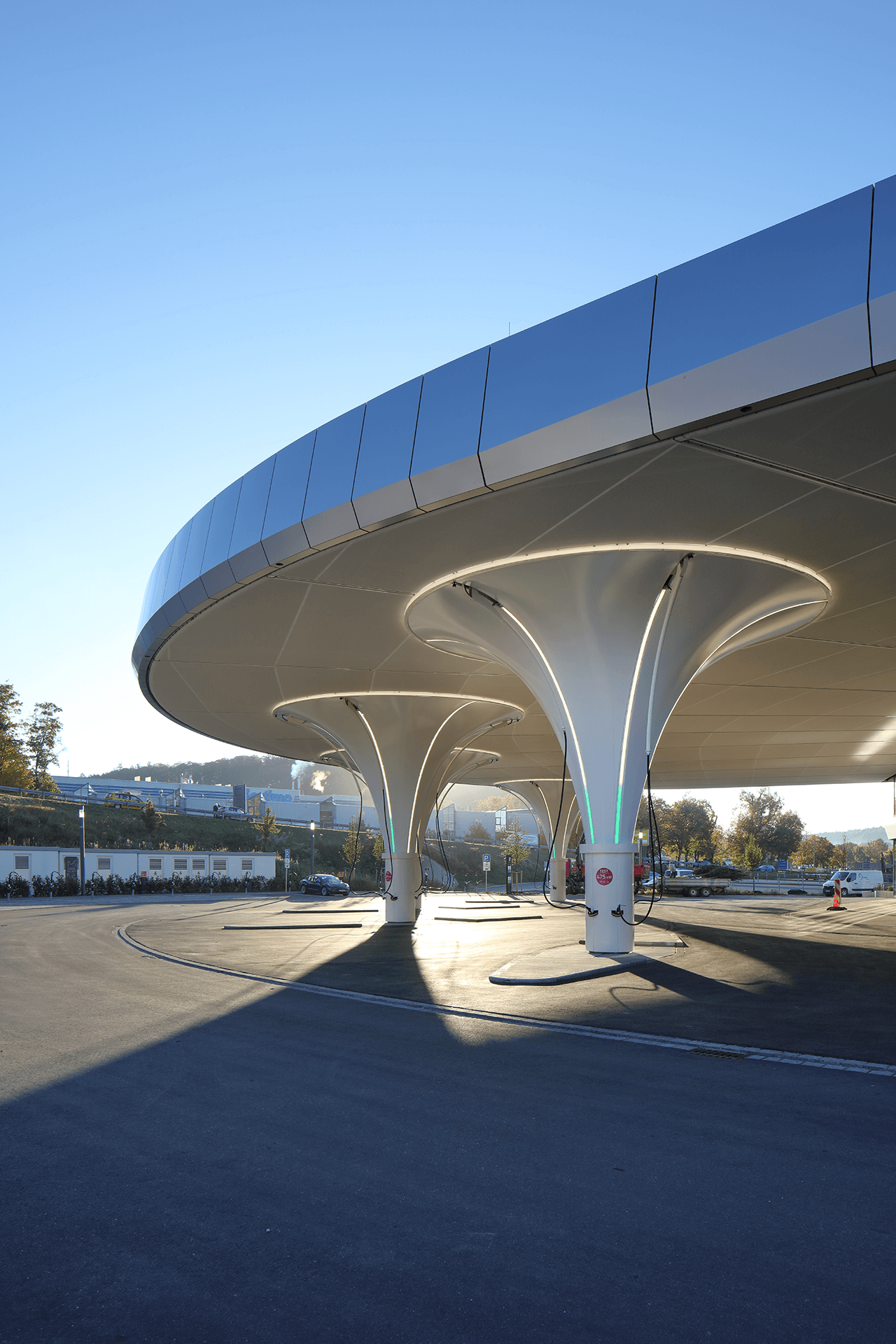

From small schools to skyline residential towers, be inspired by the building dreams that have already become reality today!

Michael Seidel

+49(0) 8225/999-19

In the anodizing process, also called anodization, the building up of a very hard and scratch-resistant aluminium oxide layer in an electrochemical process is facilitated. It protects the aluminium from direct mechanical influences and is resistant to weathering and corrosion.

Aluminium surfaces can optionally be chemically or mechanically pre-treated before anodising. This changes the structure, reflective properties and effect of the surface.

For metal sheets, we offer the pre-treatment options degreasing and deoxidising (E0) and the most common chemical pre-treatment pickling (E6). Profiles can be degreased and deoxidised (E0), ground (E1), brushed (E2), ground and micro-polished (E4) or pickled (E6).

Anodized finishes in silver and bronze tones

The timeless surfaces have been popular with planners and architects for decades. From silver to black, we offer all common colours.

SANDALOR® coloured anodizing

SANDALOR® surfaces are colourful and weather-resistant. Due to their lightfastness, the colourful shades are equally suitable for exterior and interior use.

Structural Glazing Anodizing

If required, we anodise in accordance with the guidelines of ETAG 002. The anodized layer then fulfils special requirements, so that for example glass might safely and permanently be attached and bonded.

Anodizing according to British Standard

We also anodize in accordance with British Standard (BS 3987) which is traditionally required for many façades in the UK.

Anodizing always preserves the natural aluminium look – because it is a process that changes the surface of the metal itself and does not cover it. Colour pigments are always embedded in the top layer of the metal.

The new copper anodized materials can be used to create shiny copper-orange or matt-shimmering dark red facades. The copper-colored anodized surfaces have major advantages over real copper facades: The weatherproof aluminum facades do not show the oxidation phenomena typical of copper, which result in significant color changes over time. The unsightly traces of copper corrosion cannot be found on anodized surfaces either. Our copper anodizers are available in the Terracopper 1,2,3 and Bordeaux 1,2,3 series. All copper anodized materials are offered in the usual pre-treatment variants.

25 colors can be reproduced using the SANDALOR® process.

The colors suitable for outdoor use are light-resistant and colorful.

A selection from the SANDALOR® design series:

From small schools to skyline residential towers, be inspired by the building dreams that have already become reality today!

Company

Surface finishes

References

Assistance