During the liquid coating process, aluminium components are coated with a liquid lacquers. This is afterwards baked in an industrial oven. The applied coat forms a protective layer on the substrate. In order to ensure perfect lacquer adhesion and good corrosion protection, the aluminium surface is usually pre-treated with a aluminium chromate beforehand. If a chromate-free pre-treatment is desired or if there is a risk of filiform corrosion, we work with pre-anodisation instead.

The range of design possibilities for colours, gloss effects or surface structures is enormous with this process. In terms of aesthetics and depth effect, they far surpass powder coatings.

Fluoropolymer coatings

Fluoropolymer coatings are among the most weather-proof and durable surfaces. Our special expertise lies in the application of the GSB-certified fluoropolymer system DURAFLON®. DURAFLON® can be produced in an almost unlimited range of colours. In addition, the visual and functional qualities of the coating are maintained over the entire service life of the façade. We are also a licensed partner of PPG Industries for the processing of PVDF®-fluoropolymer coatings.

Polyurethane coatings (PUR)

The weather resistance of PUR coatings is comparable to that of PE powder coatings. The PUR quality is mainly suitable for indoor use.

With wet coating, almost all solid or metallic colors can be implemented, and the finest gradations can be achieved with pinpoint accuracy. We even implement the feel and structure of the surface individually according to your wishes.

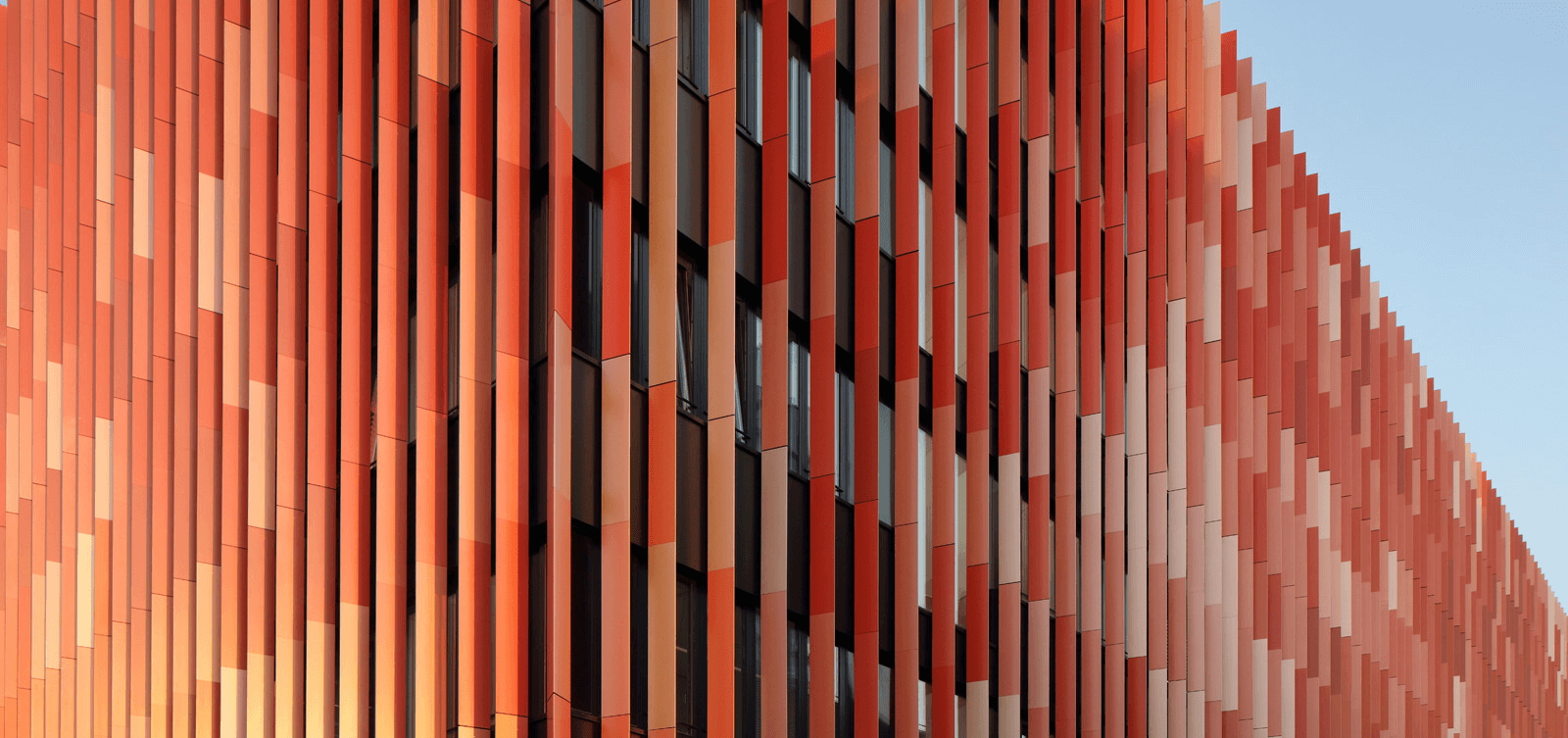

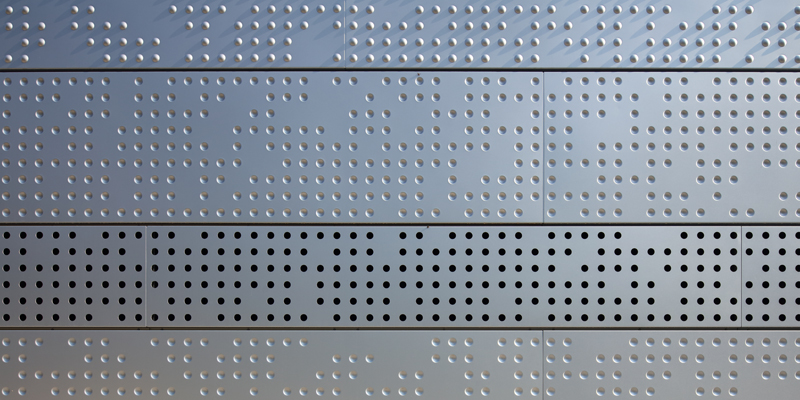

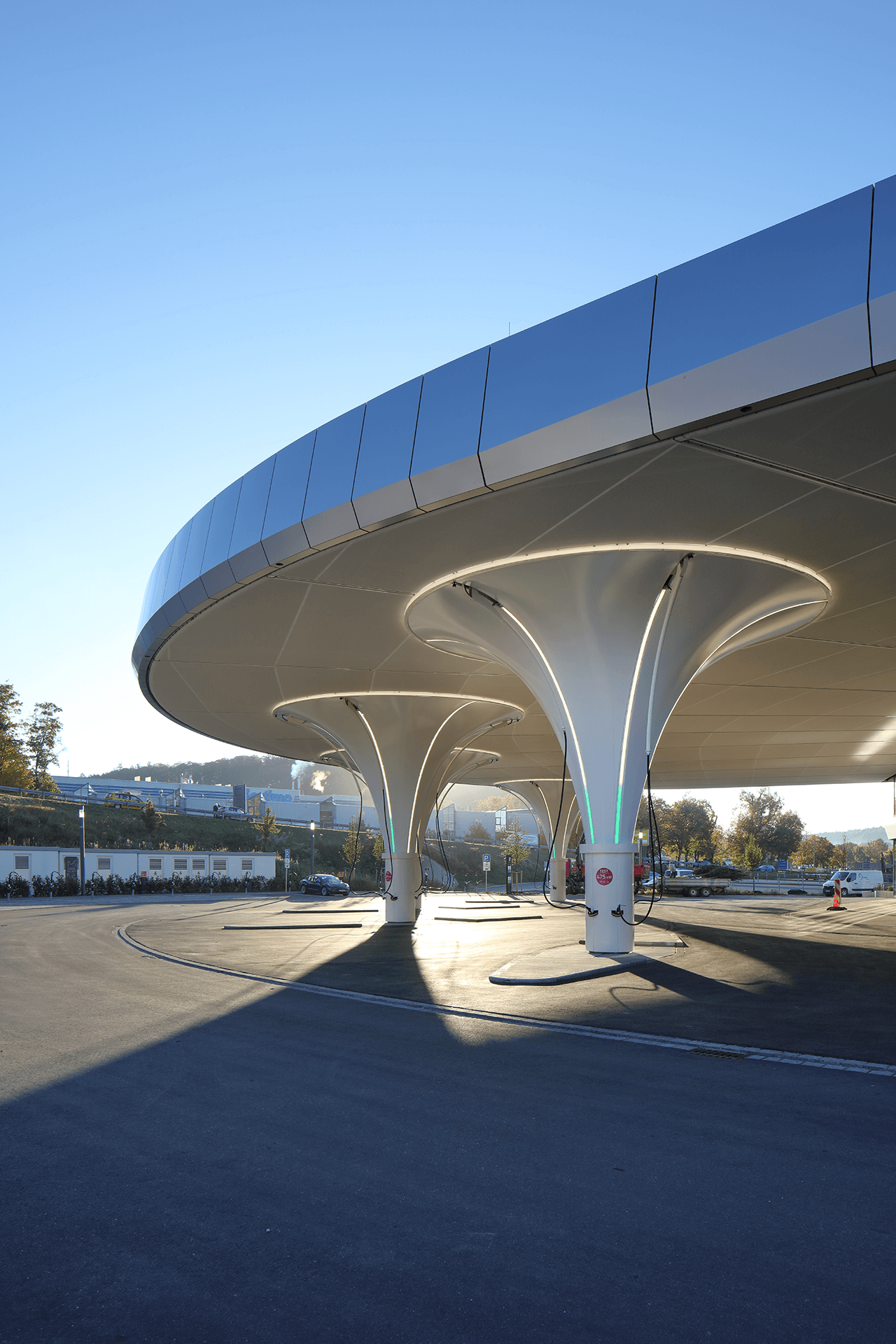

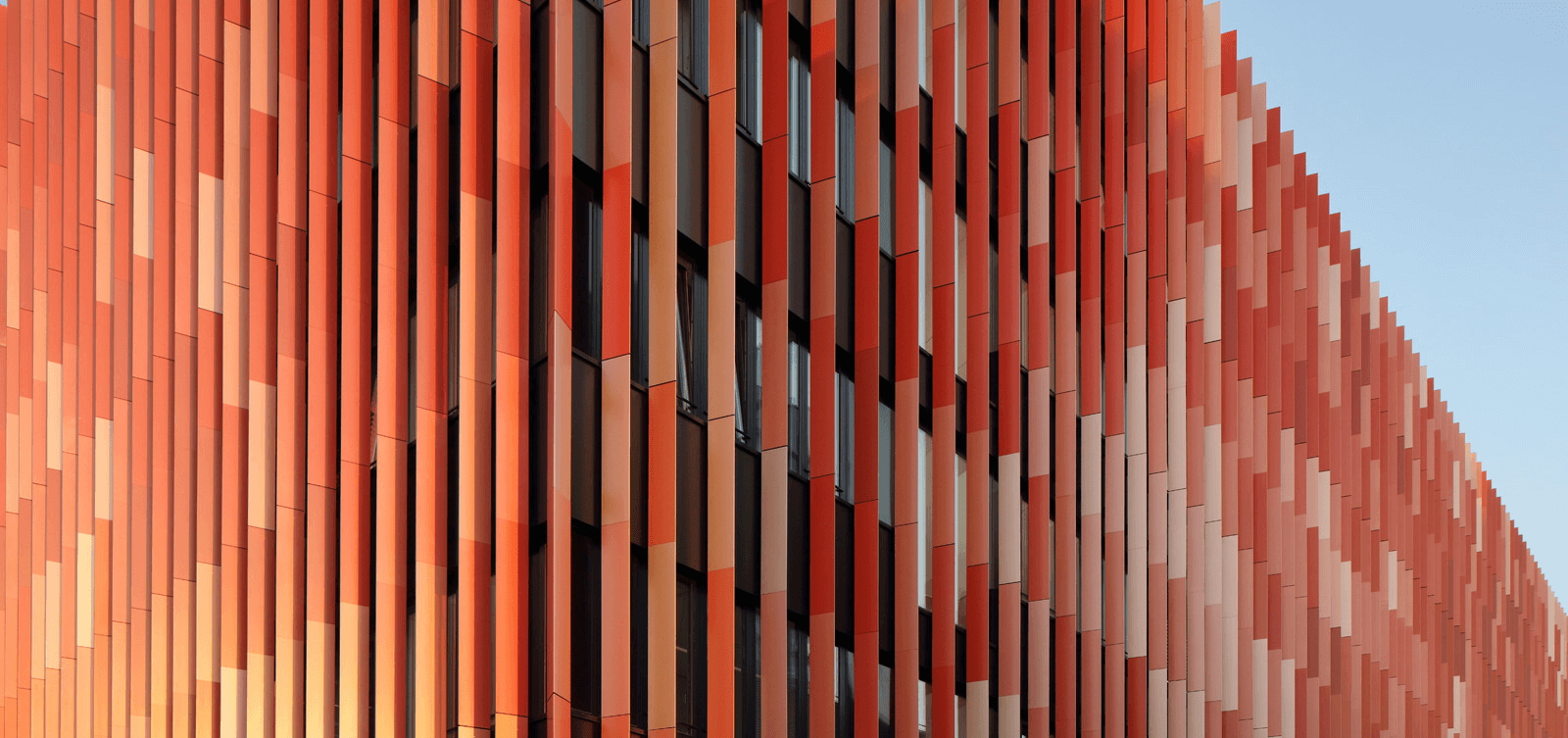

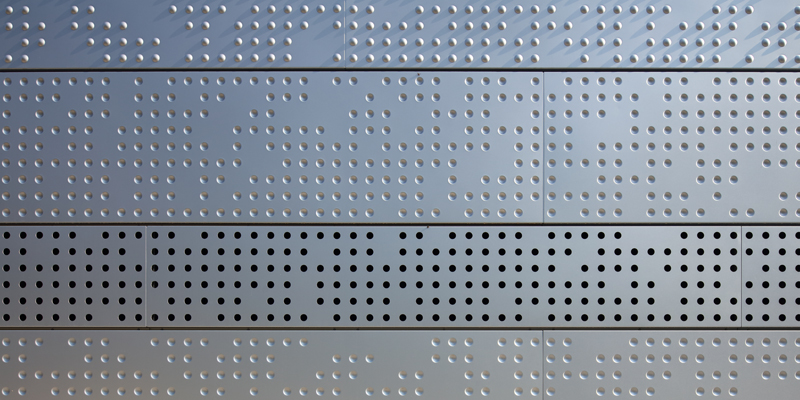

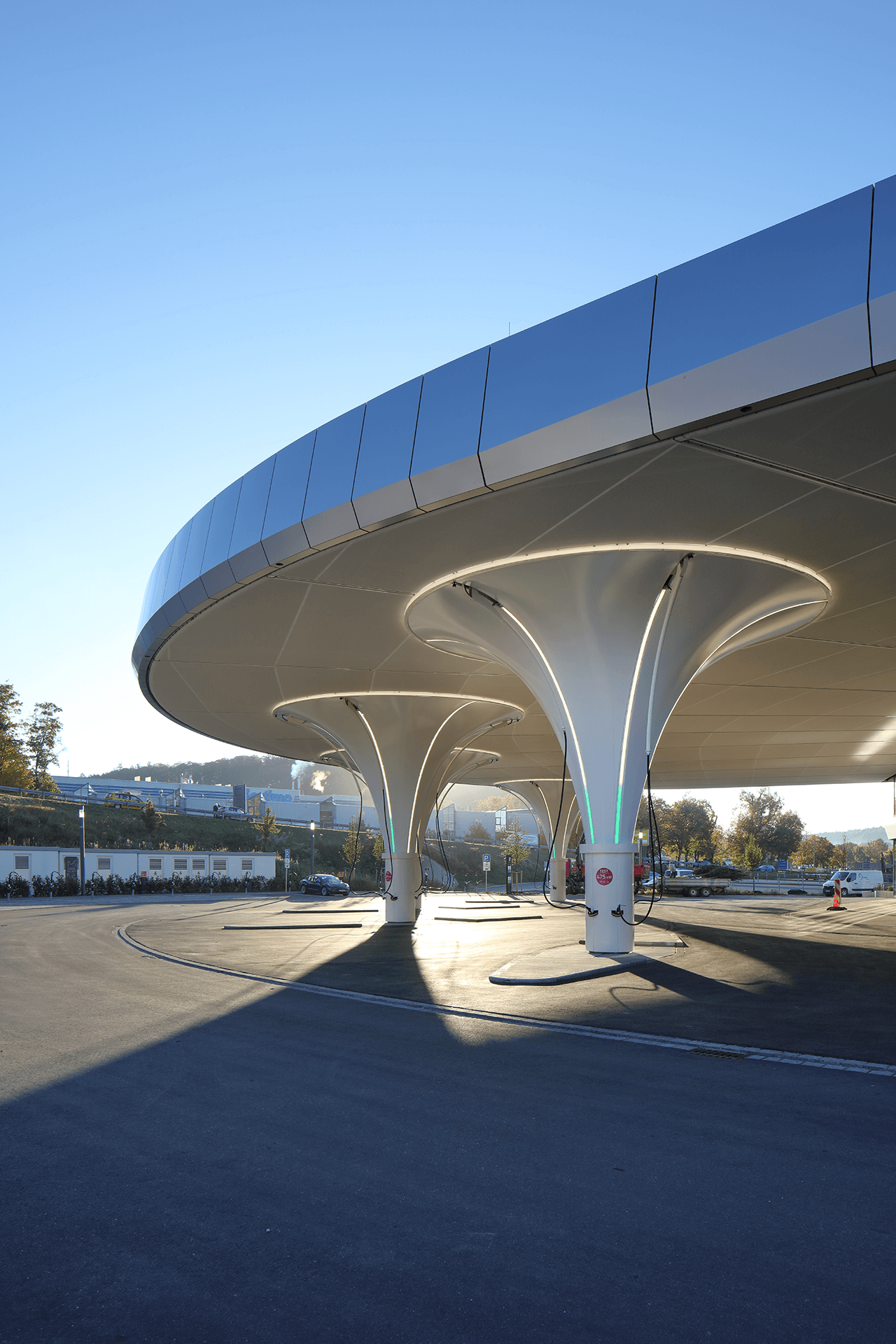

The range of design options such as colors or surface structures is very large with this process. Almost every surface can be created individually in every color. In contrast to powder coatings, wet paint systems have a strong depth effect - especially with metallic effects. Wet paints also adapt very precisely and permanently to highly complex, three-dimensional shapes, profiled sheets, perforated sheets or expanded metals. In this way, you can advantageously emphasize the effect of shapes. In terms of aesthetics and depth effect, they far surpass powder coatings.

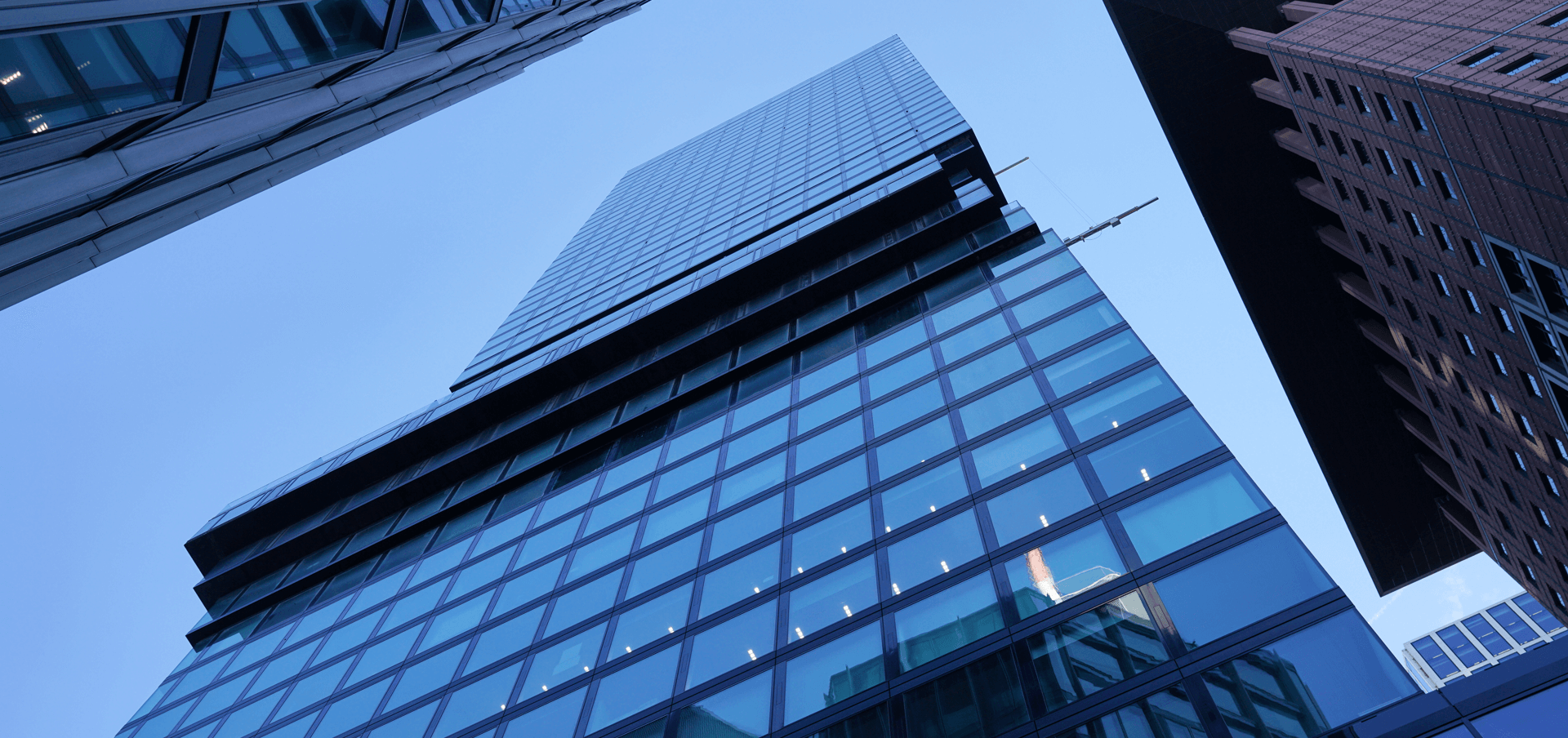

Color, shine and structure are the three essential design parameters because their carefully coordinated interaction underlines the shape of your building.

Duraflon® surfaces are possible in almost all colors of the common color ranges. Use RAL, NCS, Sikkens or other color systems for your facade concept or use our HD Wahl design series:

Please feel free to contact us with your individual color request!

Duraflon® is available as standard in the gloss levels “matt”, “semi-matt” or “satin-gloss”. Shine and brilliance ensure the depth effect of a facade surface and can be flexibly designed and used.

Profiling, expanded metal, perforated sheets or other shapes with a rough or matt surface can be integrated excitingly into architecture. Duraflon® underlines the structure of these elements and brings out their feel in a very differentiated way.

A selection from the DURAFLON® design series:

You can find more colors and surfaces on the Duraflon website.

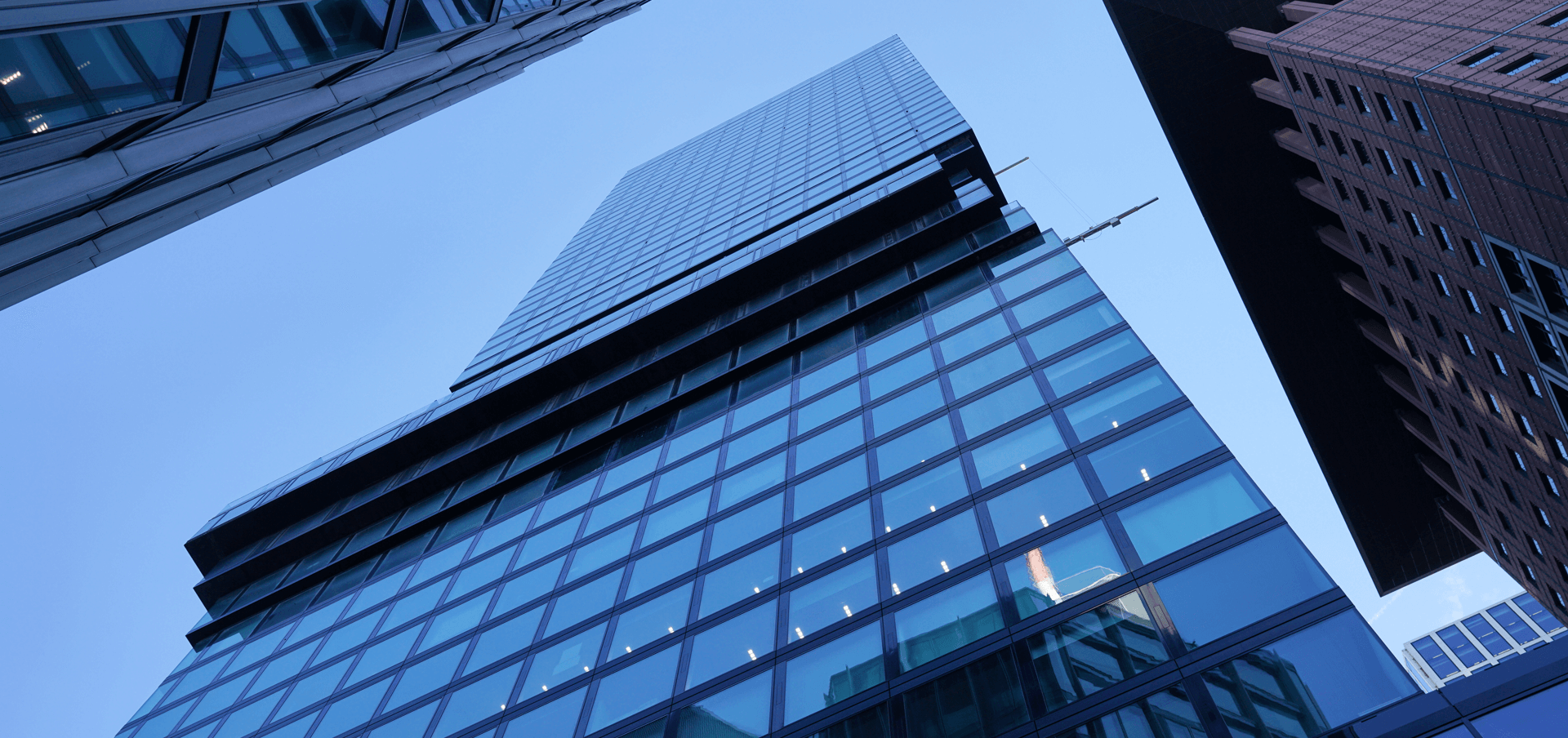

From small schools to skyline residential towers, be inspired by the building dreams that have already become reality today!

Michael Seidel

+49(0) 8225/999-19

During the liquid coating process, aluminium components are coated with a liquid lacquers. This is afterwards baked in an industrial oven. The applied coat forms a protective layer on the substrate. In order to ensure perfect lacquer adhesion and good corrosion protection, the aluminium surface is usually pre-treated with a aluminium chromate beforehand. If a chromate-free pre-treatment is desired or if there is a risk of filiform corrosion, we work with pre-anodisation instead.

The range of design possibilities for colours, gloss effects or surface structures is enormous with this process. In terms of aesthetics and depth effect, they far surpass powder coatings.

Fluoropolymer coatings

Fluoropolymer coatings are among the most weather-proof and durable surfaces. Our special expertise lies in the application of the GSB-certified fluoropolymer system DURAFLON®. DURAFLON® can be produced in an almost unlimited range of colours. In addition, the visual and functional qualities of the coating are maintained over the entire service life of the façade. We are also a licensed partner of PPG Industries for the processing of PVDF®-fluoropolymer coatings.

Polyurethane coatings (PUR)

The weather resistance of PUR coatings is comparable to that of PE powder coatings. The PUR quality is mainly suitable for indoor use.

With wet coating, almost all solid or metallic colors can be implemented, and the finest gradations can be achieved with pinpoint accuracy. We even implement the feel and structure of the surface individually according to your wishes.

The range of design options such as colors or surface structures is very large with this process. Almost every surface can be created individually in every color. In contrast to powder coatings, wet paint systems have a strong depth effect - especially with metallic effects. Wet paints also adapt very precisely and permanently to highly complex, three-dimensional shapes, profiled sheets, perforated sheets or expanded metals. In this way, you can advantageously emphasize the effect of shapes. In terms of aesthetics and depth effect, they far surpass powder coatings.

Color, shine and structure are the three essential design parameters because their carefully coordinated interaction underlines the shape of your building.

Duraflon® surfaces are possible in almost all colors of the common color ranges. Use RAL, NCS, Sikkens or other color systems for your facade concept or use our HD Wahl design series:

Please feel free to contact us with your individual color request!

Duraflon® is available as standard in the gloss levels “matt”, “semi-matt” or “satin-gloss”. Shine and brilliance ensure the depth effect of a facade surface and can be flexibly designed and used.

Profiling, expanded metal, perforated sheets or other shapes with a rough or matt surface can be integrated excitingly into architecture. Duraflon® underlines the structure of these elements and brings out their feel in a very differentiated way.

A selection from the DURAFLON® design series:

You can find more colors and surfaces on the Duraflon website.

From small schools to skyline residential towers, be inspired by the building dreams that have already become reality today!

Company

Surface finishes

References

Assistance